Product Development & R&D

Innovation & Product Development

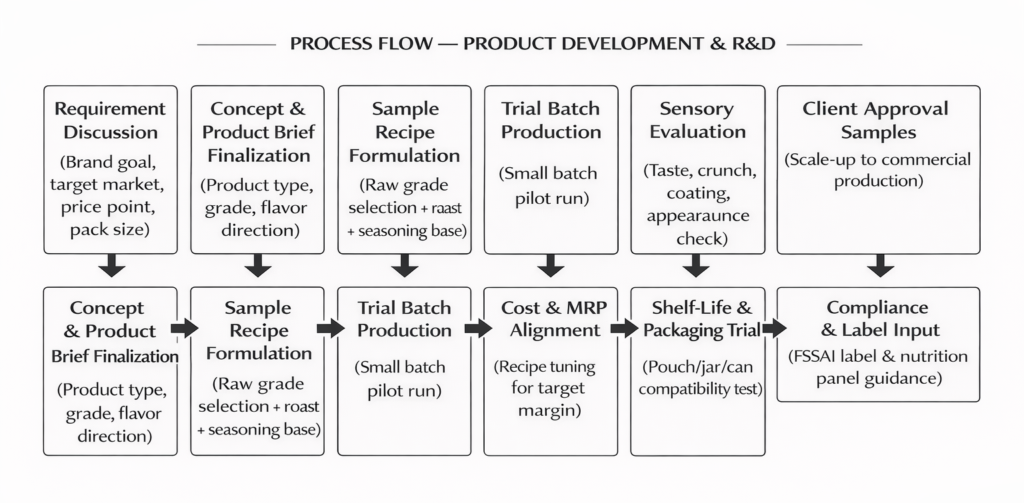

Our Product Development & R&D team works with brands and white label partners to turn ideas into market-ready makhana products. We develop and test recipes based on your target market, price point, and taste profile, then run small-batch trials to finalize flavor, roast level, crunch, and coating consistency before bulk production.

We also support custom seasoning development, texture and moisture optimization, shelf-life performance, and packaging suitability. If you have a reference product, we can match or improve it; if you’re launching new, we help you select winning flavor and format options.

The goal is simple: faster launches, stable quality, and commercially viable products.

- product trials- We carry out controlled product trials covering roast level, crunch, color, and texture performance. Multiple prototype batches are created and evaluated before finalizing the formulation. Each variation is tested for taste balance, mouthfeel, and visual appeal, helping buyers compare options and select the most suitable version before moving to scale production.

- In-house spice production– Our team also develops and refines seasoning systems through repeated flavor and coating trials. This includes spice intensity control, coating uniformity, adhesion stability, and oil vs dry application methods. We support both custom flavor creation and market-reference matching, allowing brands to build unique taste profiles or develop competitive equivalents.

- Shelf Life & Stability Testing– Shelf-life performance is another major R&D focus area. We evaluate how different roast levels, oil usage, seasoning types, and packaging materials influence crunch, aroma, and freshness over time. Based on this, we recommend suitable barrier packaging, moisture targets, and handling practices so the product performs well through storage and distribution.

- Concept to Commercialization– Process practicality is a core R&D focus. We design formulations that are production-friendly and cost-efficient at scale, not just good at sample level. Raw grade selection, moisture targets, roast parameters, and breakage control methods are optimized so bulk manufacturing delivers consistent results across batches and production cycles.

- Regulatory & Label Guidance– We support white label partners with regulatory and labeling guidance to ensure products are compliant and market-ready. Our team helps structure labels as per FSSAI requirements, including product name, ingredient list, allergen info, veg symbol, batch coding, and mandatory declarations. We also assist with the nutritional information panel format and values, along with correct serving size presentation. For flavored products, we guide on safe and compliant claim wording such as roasted, gluten-free, or no preservatives. For export orders, we provide international label format inputs and documentation guidance, helping reduce approval delays and relabeling risk.